Week 7

Date: 10/25/18 Time: 4:30-6:30pm

Week #: 7

Quick Summary:

- We now have gears and a gear track for our lift system.

- We have a TorqueNADO motor for the lift instead of the weaker motor we used to have.

- The hook on the lift is simply an axle, but it is extremely difficult to hook on and off the lander.

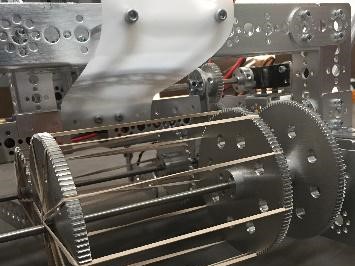

- We now have two, big, metal gears in the front of the vacuum and two, small, metal sprockets in the back. But the distance between them is too large.

- The bracing bar is moved farther back so that it no longer interferes with the arm’s path.

- We only have two wheels on each side of the robot because we are not going into the crater.

What We Accomplished: We completely redid the lift system. Instead of having the rope and pulley system with the unreliable Kevlar rope, we have gears and a gear track. We also replaced the motor with a much stronger one called a TorqueNADO. This motor is fastened with gears and an axle to a channel, where the gears ride up the gear track that is fastened to another channel. U-shaped black pieces hold the gears to the track and keep the two channels together. This system is working very well and is very reliable. The hook at the top of the lift is simply an axle put through a square channel. We altered the vacuum a little bit in order to get rid of the problem of not being able to pick up minerals. We now have 4 inch metal gears in the front and 2½ inch metal sprockets in the back. The three rubber bands above the vacuum that were causing friction got replaced with a rectangular piece of shelf liner. This has gotten rid of all friction problems, and the shelf liner is angled to kind of spit the minerals out from the top of the vacuum and into the bucket. The bracing bar was repositioned farther back on the robot so it no longer interferes with the path of the arm. The shelf liner is attached to this bar. We decided as a team that we would not go into the crater because of our strategy plans. So we got rid of the three wheels and all the connecting gears, and instead have one back wheel on each side and one omni wheel in the front on both sides of the robot.

Our Problems: We are still having problems with our vacuum if the square minerals are flat on the ground. The distance between the big gears and the small sprockets is too large, so they don’t always get sucked up. It is very inconsistent. Also, the slots in the gears and too small for the rubber bands to fit, so they keep sliding out and making big gaps in the rubber bands. The hook at the top of the lift is not working well at all because it is so hard to attach and disengage from the lander. We waste a lot of time by having to go sideways, and even that hardly ever works.